UK University Students 3D Print Record Breaking Rocket Engine

12th Jul 2023

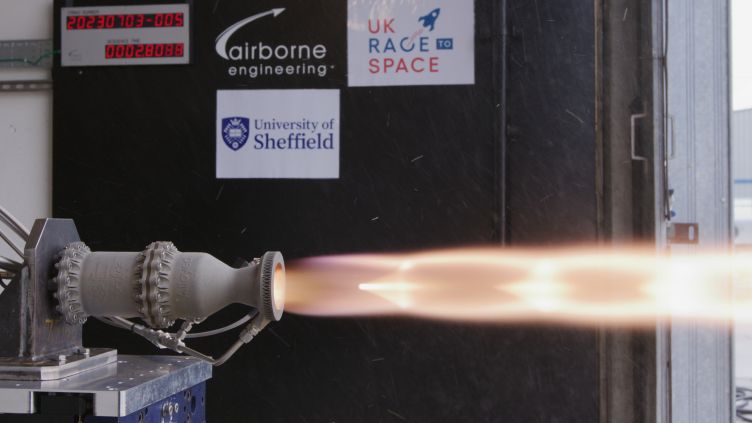

A team of engineering and science students from the University of Sheffield built a liquid rocket engine using metallic 3D printing. The student team known as Sunride successfully completed a hotfire test of the ‘Sunfire’ liquid engine, which until recently, was the first 3D printed engine built in the UK and the first built by students.

The University of Sheffield called the engine: “the most powerful student-built engine of its type.” Adding, “there are only a handful of liquid rocket engines made by students throughout Europe… [and not] as powerful as the engine built at Sheffield.” The students hope to use the engine to power their own rocket over the coming years.

Sunfire: The Liquid Rocket Engine

Sunfire, the metallic 3D printed liquid rocket engine utilises both fuel and an oxidiser over conventional oxygen breathing that most jet engines use. They also designed the engine to be regen-cooled, which uses fuel to cool the combustion chamber before it is burnt in order to augment efficiency and prevent weight issues.

The University of Sheffield’s Royce Discovery Centre instrumentally tested the laser-powder-bed metallic 3D printing machine that built the engine. And once printing was complete, the university’s Advanced Manufacturing Research Centre and Faculty of Engineering machined the engine to ensure it was ready for the hotfire test.

Taking A Student Project To The Next Level

Part of the week-long ‘Race to Space’ competition, student teams from across the UK tested their rocket engines built over the past two academic years. Subsequently, this led to breaking an unofficial record for performing the most liquid/hybrid hotfire rocket engine tests on one site in a week.

The project was part of the universities Space Initiative, designed to assist STEM students in using their skills to overcome some of the biggest challenges facing the space industry, in addition to aiding their career development post graduation.

Is 3D Printing The Way Of The Future?

3D printing has become highly reliable, and the student-built engine arises from a spate of commercial projects using this method of space technology manufacturing. Edinburgh-based Skyrora used their Skyprint 2 3D-printer to build a 70kN engine. And in 2021, Orbex ordered a large 3D printing machine to expedite their rocket engine manufacturing.

Relativity Space’s entirely 3D printed Terran 1 rocket was deemed a success when it was tested earlier this year. Although an anomaly occurred with the upper stage, it was another move where 3D printing was successfully used in space technology production. Across the pond, Australia’s Gilmour Space Technologies is also investing in 3D printing in order to fabricate their space components and high-performance rocket parts.

Using The Engine To Reach New Heights

Sunride are aiming to use the engine to power their own rocket that will be launched beyond the Kármán line – the border between the Earth’s atmosphere and 62 miles above sea level. Currently, Sunride possess the UK altitude record when they launched their amateur rocket in 2019.

Thank you for your comment! It will be visible on the site after moderation.