Easing the way to the stars: 3D Printing in Space

18th Aug 2022

3D printing is an additive manufacturing technology. The invention belongs to an American chemical engineer, Charles Hull, who in 1986 designed the first stereolithographic three-dimensional printer. Two years later, Carl Deckard, a student at the University of Texas at Austin, invented Selective Laser Sintering (SLS) process central to today’s 3D printers.

Over time, 3D printing has evolved into a high-performance technology used in a wide range of applications, from construction and agriculture to medicine and the aerospace industry. This is not surprising because “rapid prototyping” has many advantages: increased productivity and efficiency. Objects created on a 3D printer can weigh less and be stronger than those created by traditional methods. In this article, we will look at how 3D printing can boost our possibilities in space travel.

What role could 3D printing have in space?

3D printing in space is a great way to reduce the running costs of missions and increase their duration. After all, everything astronauts may require in orbit or on other planets can be created right on the spot, without delivering cargoes from Earth every time.

A small production plant, which will always be on-site, will make it possible to create everything necessary for long journeys and the repair of damaged units directly on board the spacecraft or station located at the other end of the solar system. Just think about it! It will be possible to print almost everything — spare parts for spaceships, stations, tools, spacesuits, food, building materials, and more. And this is not just a distant dream but something rapidly becoming a reality at hand.

How is 3D Printing Used in Space Exploration?

Humanity has been using 3D printing in the space industry since the 2000s. Projects for the creation of rocket engines are in special demand.

For example, the injectors, combustion chambers, and pumps of Rocket Lab’s Rutherford rocket engine are printed using electron beam melting. Their upper stages, Curie and HyperCurie, are produced using the same technology. And today, the Electron rocket is one of the most sought-after launchers for delivering CubeSats to LEO.

The 3D-printed seamless liquid engine of Britain’s first reusable rocket, Orbex Prime, is expected to be 20% more effective than traditional engines. And the Terran R of the American company Relativity Space may become the first fully printed and reusable rocket to launch over 20 tonnes of cargo into orbit.

Aerospace giants Aerojet Rocketdyne, Boeing, Airbus, and SpaceX, have been using additive technologies in their manufacturing for a long time. For example, SpaceX has made a major bet on metal printing (DMLS), allowing it to build one of the world’s most economical and reliable launch vehicles — Falcon 9. The same technology is at the core of Starship, a space-based interplanetary transportation system that could pioneer the colonization of the Moon and Mars as soon as next year. Also, SpaceX produces astronaut helmets using 3D printing technology with PEEK plastic.

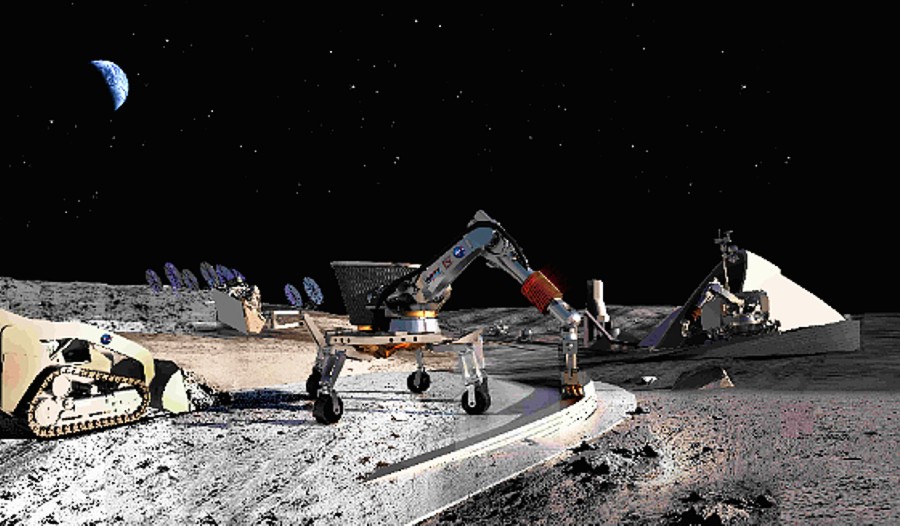

Special teams from NASA and the European Space Agency (ESA) are developing printed electronics for humidity and CO2 measurements and crew health monitoring, which may be printed on ISS in the coming years. Also, these space agencies are seriously considering the possibility of using 3D printers for creating large-scale objects, such as residential, production station modules, houses, etc.

What materials are used for 3D printing in space?

3D printers for the space industry mainly use metal powders, basalt fibres, and composite materials that can withstand ultra-high temperatures. For example, the Made in Space company uses high-strength polyesterimide/polycarbonate or PEI/PC for its Archinaut 3D printer. In particular, PEI/PC is resistant to UV radiation and atomic oxygen.

The AMAZE project for printing metal parts in zero gravity involves using a device based on inkjet printing technology from heat-resistant tungsten. In 2013, Deep Space Industries, which plans to mine asteroids, undertook the development of a printer that can use iron-nickel alloy (the main component of asteroids) as a raw material. And Planetary Resources conducted an experiment in an Earth laboratory by printing a small design from a powdered metal meteorite.

But unique, unexpected, or even yet unknown materials may be used. In 2013, an ESA-led project explored the possibility of using regolith — the loose top layer of lunar soil — to produce a 1.5-tonne hollow-cell building block intended as part of a lunar base shelter dome.

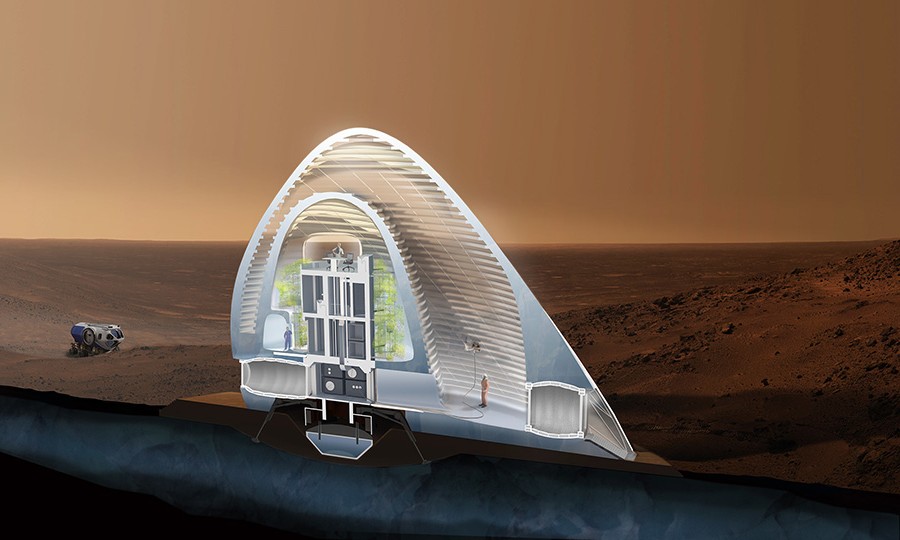

NASA went even further. In 2017, the Agency announced the Centennial Challenge Mars Habitat Competition, the main idea of which was to create a housing project on Mars using Martian ice! Ice was chosen as a building material for a reason. Unlike regolith, it is translucent and can also shield astronauts from radiation.

How is 3D food printing used in space?

In 2013, NASA announced funding for the development of a 3D printer that could create food for the astronauts. The technology involves cooking ingredients stored in powder form in special cartridges. The printer will mix the cartridge contents, add water or oil, and produce various dishes.

The first thing that will be available from 3D printing food in space is pizza. The printer will prepare the pizza layer by layer. First comes the dough, then the tomato base, and protein filler. A variety of sources can be used as protein, i.e., meat (including insects), milk, and various plants (for example, algae). One food cartridge iwill last for 30 years of operation. This means that it can be used at first on the ISS, but then on the Moon or Mars when we settle down there.

When was 3D printing first used in space?

An ISM joint project by NASA and Made in Space tested the first 3D printer in space in 2014. The printer used the fused filament fabrication (FFF) process. In this process, the printer feeds a continuous polymer filament through a heated extruder onto a tray to create a three-dimensional object. The experiment took place on the ISS in microgravity. The ISS printer produced dozens of components, which researchers compared to those made on Earth. The analysis showed that microgravity had no significant impact on the process from an engineering point of view.

Does the ISS have a 3D printer now?

The ISS has AMF (Additive Manufacturing Facility), developed by Made in Space two years after successful experiments with the first 3D printer. One of the first test parts that the machine printed in space was a wrench. Today, AMF is a permanent production facility at ISS, which has created many of the functional elements necessary for the station’s operation. In particular, it has built a part of an antenna, an adapter for holding the probe in the air outlet of the oxygen generation system, a part for connecting two spheres of free-flying robots used for research on the space station, and more.

What type of 3D printer is on the ISS?

AMF uses an extrusion-based 3D printing method. It can produce components from various space-grade composites, including flexible polymers. The unit is installed in the EXPRESS Rack on the middle deck, where the crew can easily access it at any time.

In 2019, Made in Space launched a Recycler at ISS to explore the possibility of printing from recycled materials. The machine explores which materials are most effective for processing into threads and can withstand repeated use without degrading. The technology should help relieve future long-term research missions from having to carry a large supply of 3D printing material as cargo.

What are some problems with 3D printing in space?

The microgravity found on the ISS ensures a relatively normal printing process onboard. But can you 3D print in zero gravity? It is a very hard task. The main problem is ensuring that the layers connect before they cool and dry completely. The simplest solution is to use a sticky material between layers, but it would be difficult to avoid sticking to the printer’s build plates, which could lead to damage to the printed component.

Another big challenge of 3d printing in space is insufficient printing accuracy. Additive manufacturing in space cannot rely on the same processes as on Earth. After all, the printed component has no support. Astronauts cannot place them on the assembly tray, and the printer makes them in a next-to-complete vacuum. Because of this, the resulting parts often have imperfect surfaces and are highly porous. Using such components without first refining them will most likely lead to cracks, damage, and, as a result, disasters.

Reliable 3D printing Reliable technology for other planets is a problem, too. Temperature swings, meteor showers, and a new environment are only part of the list of problems that early printers on the Moon and Mars will face, but NASA and ESA are actively looking for a solution.

Final word

Even though additive manufacturing is not a universal solution, it is one of the most promising tech development areas, particularly in space exploration. The applications of 3D printing in space are increasing, and, soon enough, we may see the result of their work not only in orbits but also in deep space.

Thank you for your comment! It will be visible on the site after moderation.