Skyrora Completes A Successful 70kN Rocket Engine Test

3rd Jun 2022

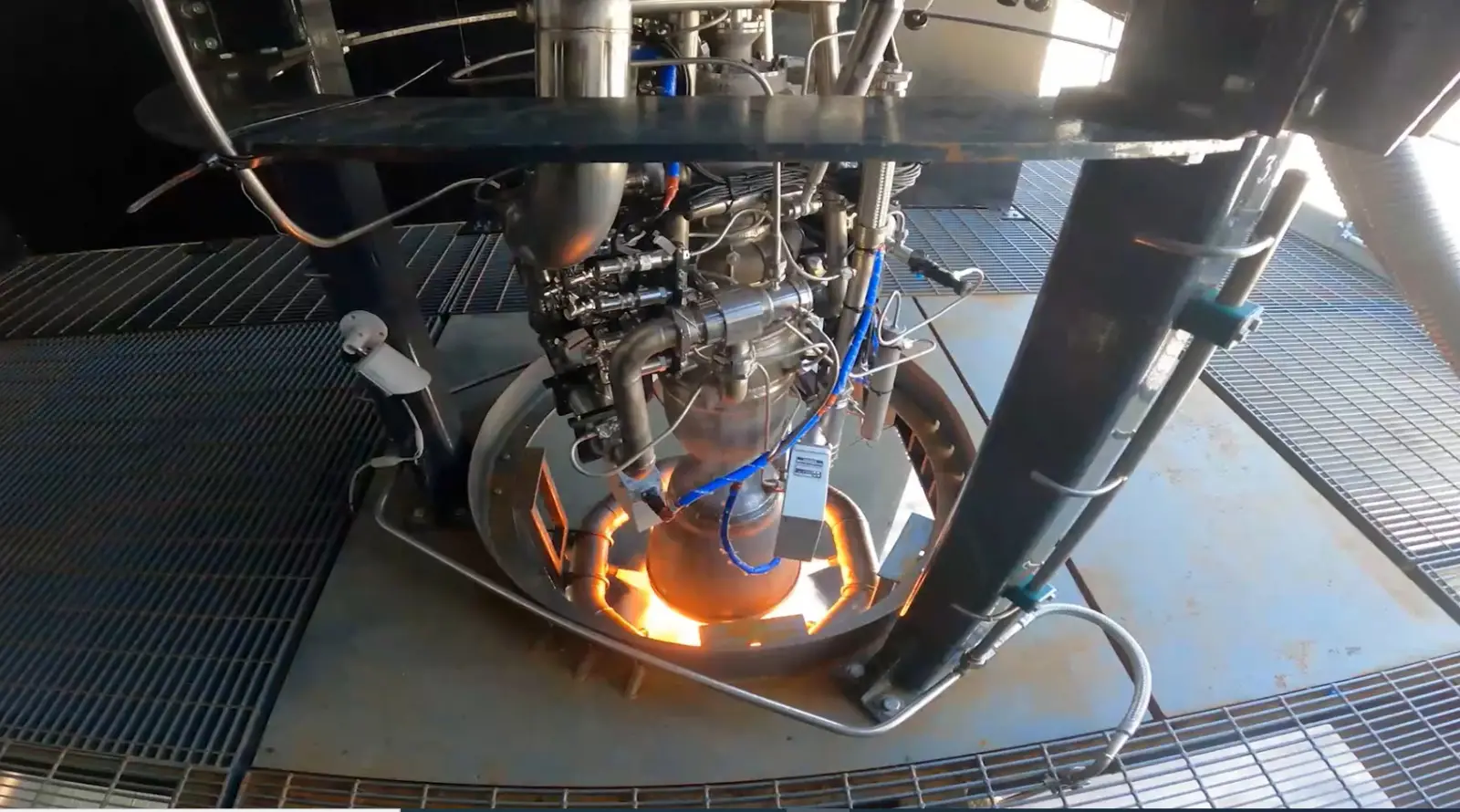

Skyrora has performed and documented a successful 70kN rocket engine test, with the engine being entirely 3D-printed. With this, the Edinburgh-based rocket company has achieved a chief milestone in the contract it has under the Commercial Space Transportation Services and Support Programme (CSTS) with the European Space Agency (ESA).

Skyrora can now move on to the next stage of qualification tests, ensuring the business is one step closer to the main objective of orbital launch.

The unique design of the 70kN rocket engine

The 70kN rocket engine is going to be the first staged combustion engine on HTP, high-test peroxide, after qualification. The company’s orbital engine, which the company designed and created on-site at their newly launched vehicle assembly premises, is a key element of the XL orbital vehicle.

The engine was entirely 3D printed, and the company announced it has generated the biggest 3D hybrid printer of its type in Europe, SkyPrint 2. This will come into operation later this year.

An insight into the 70kN rocket engine test

This test, which is the latest in a series of 16, took 20 seconds to complete. It was carried out at Skyrora’s test site in Gorebridge, Midlothian, which opened a few months ago. It is the biggest of its kind in the United Kingdom.

The test was complete within the required parameters, using a different propellant mixture ratio.

As a consequence of the successful completion of the test, Skyrora is now in the process of scaling up its manufacturing efforts. They will now oversee qualification tests on one engine per week.

Volodymyr Levykin, the founder and CEO of Skyrora, said the following:

“Without the tireless efforts of our international team, this milestone wouldn’t have been possible. Everybody’s insights have been invaluable, and their spirit is a true testament to the passion shared by everyone at Skyrora.”

Sustainable rocket launches

Skyrora has shown their commitment to launching in the most sustainable manner attainable, which is certainly aided by their local test facility and in-house manufacturing capabilities. This lowers the company’s carbon footprint considerably.

Thank you for your comment! It will be visible on the site after moderation.